Scan the wechat code for consultation

Focusing on Plastics for 20 Years. We specialize in selling imported plastic raw materials in original factory-standard packaging, boxed (off-grade). Annual Sales: 2,000 tons of PEEK. Target: 3,000 tons. In-stock. Quality Assured. Fast Delivery! We now offer the following specifications of raw materials, sheets, and rods to all customers at our most competitive prices. A single call resolves all your PEEK inquiries. Contact us today: +135 38586 433 (Peach) +188 1699 6168 (David) 专注塑料20年,专业销售进口塑料原料,原厂标准包装,箱装(副牌), 年销PEEK 2000吨,预期目标3000吨, 库存充足,品质保障,交货快捷!现面向全球新老客户再次以最惠价格供应如下规格型号原材料,板材,棒材, 一通电话解决您所有PEEK材料的疑问,欢迎来电咨询: +13538586433 (Peach) +18816996168 (David)

Focusing on Plastics for 20 Years. We specialize in selling imported plastic raw materials in original factory-standard packaging, boxed (off-grade). Annual Sales: 2,000 tons of PEEK. Target: 3,000 tons. In-stock. Quality Assured. Fast Delivery! We now offer the following specifications of raw materials, sheets, and rods to all customers at our most competitive prices. A single call resolves all your PEEK inquiries. Contact us today: +135 38586 433 (Peach) +188 1699 6168 (David) 专注塑料20年,专业销售进口塑料原料,原厂标准包装,箱装(副牌), 年销PEEK 2000吨,预期目标3000吨, 库存充足,品质保障,交货快捷!现面向全球新老客户再次以最惠价格供应如下规格型号原材料,板材,棒材, 一通电话解决您所有PEEK材料的疑问,欢迎来电咨询: +13538586433 (Peach) +18816996168 (David)

Focusing on Plastics for 20 Years. We specialize in selling imported plastic raw materials in original factory-standard packaging, boxed (off-grade). Annual Sales: 2,000 tons of PEEK. Target: 3,000 tons. In-stock. Quality Assured. Fast Delivery! We now offer the following specifications of raw materials, sheets, and rods to all customers at our most competitive prices. A single call resolves all your PEEK inquiries. Contact us today: +135 38586 433 (Peach) +188 1699 6168 (David) 专注塑料20年,专业销售进口塑料原料,原厂标准包装,箱装(副牌), 年销PEEK 2000吨,预期目标3000吨, 库存充足,品质保障,交货快捷!现面向全球新老客户再次以最惠价格供应如下规格型号原材料,板材,棒材, 一通电话解决您所有PEEK材料的疑问,欢迎来电咨询: +13538586433 (Peach) +18816996168 (David)

Avient Corporation Polyamide 6 (Nylon 6) PA6+MoS2 Bergamid™ B75 MOS2 Avient Corporation Polyamide 6 (Nylon 6) PA6+MoS2 Bergamid™ B70 MoS2 Avient Corporation Polyamide 6 (Nylon 6) PA6+MoS2 Bergamid™ B70 MoS2 BLACK T 70 Avient Corporation Polyamide 6 (Nylon 6) PA6+MoS2 Bergamid™ B70 G30 MoS2 Celanese Corporation Polyamide 6 (Nylon 6) PA6+MoS2 Nylon 6 MOS2 filled steel grey NMS2-01 SGY Envalior Polyamide 66 (Nylon 66) PA66+MoS2 Nylatron® GS Envalior Polyamide 66 (Nylon 66) PA66+MoS2 Nylatron® GS-HS Envalior Polyamide 66 (Nylon 66) PA66+MoS2 Nylatron® GS-51

CHI MEI CORPORATION 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 POLYLAC® PA-765A Polymer Compounders Limited 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 ABSCOM® FR1000 Bhansali Engineering Polymers Limited 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 Abstron AN450N ANSA TERMOPLASTICI s.r.l. 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 ANSALAC ABS V0 ALL COLOR Aurora Material Solutions, LLC 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 AuroraGuard™ ENV00-NC700 Bada AG 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 BADALAC® UL ABS 30 FR01 Novacel Co., Ltd. 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 Cevian® SER91A Novacel Co., Ltd. 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 Cevian® SER91H Americhem 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 ColorFast® FRA202 Americhem 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 ColorFast® FRA202UV Americhem 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 ColorFast® FRA204 Americhem 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 ColorFast® FRA205UV China Petrochemical Development Corporation 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 CPDC ABNF04 China Petrochemical Development Corporation 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 CPDC ABNN00AS SABIC 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 CYCOLAC™ Resin FR15 - Americas SABIC 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 CYCOLAC™ Resin FR15 - Asia SABIC 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 CYCOLAC™ Resin FR15U - Americas SABIC 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 CYCOLAC™ Resin FR15U - Asia Ester Industries Ltd. 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 ESTOPLAST SR 4000NN01 Techno-UMG Co., Ltd. 丙烯腈丁二烯苯乙烯(ABS) 0.4-1.5mm阻燃V0 EXCELLOY EKF55

WPP(Washington Penn Plastic Co. Inc.) PPH3MF3 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPH3MF2 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPH3MF1 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPH3G2.5M1.5 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPH2MF4 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPH2MF3 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPH2MF2 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPH2MF1 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPH1MG4 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPC6MF4 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPC6MF3 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPC6MF2 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPC6MF1 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPC5MF4 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPC5MF3 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPC5MF2 Mica Filled WPP(Washington Penn Plastic Co. Inc.) PPC5MF1 Mica Filled WPP(Washington Penn Plastic Co. Inc.) 511 Extrusion WPP(Washington Penn Plastic Co. Inc.) Vistamax 6102 Extrusion WPP(Washington Penn Plastic Co. Inc.) UPIL001 Extrusion WPP(Washington Penn Plastic Co. Inc.) UC9K005 NH Extrusion WPP(Washington Penn Plastic Co. Inc.) UC2I002 Extrusion WPP(Washington Penn Plastic Co. Inc.) TPO 7691 Extrusion WPP(Washington Penn Plastic Co. Inc.) PRC2CEL2.0 Extrusion WPP(Washington Penn Plastic Co. Inc.) PPHL4CF3.5-P Extrusion WPP(Washington Penn Plastic Co. Inc.) PPH1UFO Extrusion WPP(Washington Penn Plastic Co. Inc.) PPH1TF2 Extrusion WPP(Washington Penn Plastic Co. Inc.) PPH1CF4 Extrusion WPP(Washington Penn Plastic Co. Inc.) PPC1UFO Extrusion WPP(Washington Penn Plastic Co. Inc.) PPC1TF2 Extrusion WPP(Washington Penn Plastic Co. Inc.) PPC1GF2 Extrusion WPP(Washington Penn Plastic Co. Inc.) PPC1GF1 Extrusion WPP(Washington Penn Plastic Co. Inc.) PPC1GF1.5 Extrusion WPP(Washington Penn Plastic Co. Inc.) PPC1FR6 Extrusion WPP(Washington Penn Plastic Co. Inc.) PPC1FR4.5 Extrusion WPP(Washington Penn Plastic Co. Inc.) PPC1CF2F Extrusion WPP(Washington Penn Plastic Co. Inc.) PELL1SIL6.6 ExtrusionHDPE Extrusion WPP(Washington Penn Plastic Co. Inc.) 3827 UL Grades WPP(Washington Penn Plastic Co. Inc.) 3827 Unfilled WPP(Washington Penn Plastic Co. Inc.) 261NUL Unfilled WPP(Washington Penn Plastic Co. Inc.) 2194 HF Unfilled WPP(Washington Penn Plastic Co. Inc.) 761 Unfilled WPP(Washington Penn Plastic Co. Inc.) 751 Unfilled WPP(Washington Penn Plastic Co. Inc.) 731P Unfilled WPP(Washington Penn Plastic Co. Inc.) 461CA Unfilled WPP(Washington Penn Plastic Co. Inc.) 461C Unfilled WPP(Washington Penn Plastic Co. Inc.) 351 Unfilled WPP(Washington Penn Plastic Co. Inc.) 351J Unfilled

Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A2 H J10 BK 9005/A Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A2 H J10 NC 1102/E Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A2 HH D14 NC 1102/2 Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A2 HH J14 BK 9005/2 Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A2 HH J16 NC 1102/2B Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A2 HHR J16 BK 9005/UV/2 Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A3 D10 BK 9005/G Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A3 D10 NC 1102/R Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A3 D15 BK 9011/G Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A3 H J13 NC 1102/TT/01 Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A3 H J18 BK 9005/3 Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A3 H J20 BK 2000/UV/1 Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A3 H J20 BK 9005/2 Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A3 H J20 NC 1102/T/01 Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A3 J10 BK 9005/E Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A3 J10 NC 1102/E Weatherproof & UV-resistant impact-modified PA66 Celanese Corporation Polyamide 66 (PA66), commonly known as Nylon 66 Celanyl® A3 J20 NC 1102/E Weatherproof & UV-resistant impact-modified PA66 Ponci Corpration Polyamide 66 (PA66), commonly known as Nylon 66 Poncimid® ST801AW-1000NT Weatherproof & UV-resistant impact-modified PA66 Ponci Corpration Polyamide 66 (PA66), commonly known as Nylon 66 Poncimid® ST801AW-1000BK

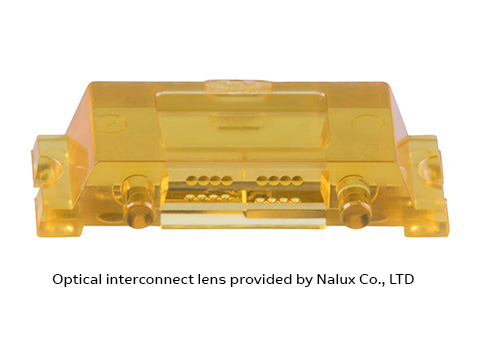

ULTEM™ RESINS ULTEM™ resin is a Polyetherimide (PEI), which offers a unique combination of thermal performance, high modulus, dimensional stability, near-infrared transparency, and non-halogenated FR for a wide range of demanding applications. EXTEM™ resin is well-suited for applications that require a higher thermal performance, such as co-packaged optical components. SILTEM™ resin is an easy extrudable amorphous copolymer with no intentionally added PFAS for potential use in applications such as high-performance ULTEM™ resin is a Polyetherimide (PEI), which offers a unique combination of thermal performance, high modulus, dimensional stability, near-infrared transparency, and non-halogenated FR for a wide range of demanding applications. EXTEM™ resin is well-suited for applications that require a higher thermal performance, such as co-packaged optical components. SILTEM™ resin is an easy extrudable amorphous copolymer with no intentionally added PFAS for potential use in applications such as high-performance wires and cables. The ULTEM™ resin family of amorphous thermoplastic polyetherimide (PEI) materials offers outstanding elevated thermal resistance, high strength and stiffness, and broad chemical resistance. ULTEM resins are available in transparent and opaque custom colors, as well as glass filled grades. These materials uniquely balance both mechanical properties and processability, offering design engineers exceptional flexibility and freedom. Also available are ULTEM copolymers which support even higher heat, chemical and elasticity needs. An ISCC+ certified renewable bio-based portfolio has recently been launched, offering sustainability benefits with interchangeable performance.

PA66 Compounds PA6 Compounds PC Compounds PC Alloys PBT & PET Compounds ABS & ASA Compounds PP Compounds Long glass fibre LGF-PP Thermoplastic Elastomers TPE-S Vulcanized Thermoplastic Elastimers TPE-V Thermoplastic Elastomers TPC

PLEXIGLAS® 8N PLEXIGLAS® 8N is an amorphous thermoplastic molding compound (PMMA) with a high heat deflection temperature under load. Slightly inferior flow to PLEXIGLAS® 7N PLEXIGLAS® 8N plus PLEXIGLAS® 8N plus is a ductile material solution developed to ensure special part specific requirements, e.g. easy demolding of injection molded parts.

PLEXIGLAS® 7M is based on polymethyl methacrylate (PMMA). Special properties of PLEXIGLAS® 7M better flowing behavior AMECA listing Applications PLEXIGLAS® 7M is particularly suitable for extruding profiles and panels for use in lighting engineering. Examples Lighting fixtures, displays and similar extruded items for technical purposes.

Glass fiber-reinforced (30%), medium viscosity polyether ether ketone VESTAKEEP®2000 GF30 is a medium-viscosity, glass fiber-reinforced (30%) polyether ether ketone for injection molding. The semi-crystalline polymer features superior mechanical, thermal, and chemical resistance. Parts made from VESTAKEEP® 2000 GF30 are of low flammability. VESTAKEEP® 2000 GF30 can be processed by common injection-molding machines for thermoplastics. We recommend a melt temperature between 380°C and 400°C during the injection molding process. The mold temperature should be within a range of 160°C to 200°C, preferably 180°C. VESTAKEEP® 2000 GF30 is supplied as cylindrical pellets in 25kg boxes with moisture-proof polyethylene liners. Pigmentation may affect values. Inside the original and undamaged packaging, the product has a shelf life of at least 2 years when stored in dry rooms at temperatures not exceeding 30°C. For information about processing of VESTAKEEP 2000 GF30, please follow the general recommendations in our brochure “VESTAKEEP® PEEK Processing Guidelines“. The values presented are typical or average values, they do not constitute a specification.

Carbon fiber-reinforced, medium viscosity polyether ether ketone VESTAKEEP® 2000 CF30 is a medium-viscosity, carbon fiber-reinforced (30%) polyether ether ketone for injection molding. The semi-crystalline polymer features superior, mechanical, thermal and chemical resistance. Parts made from VESTAKEEP® 2000 CF30 are of low flammability. VESTAKEEP® 2000 CF30 can be processed by common injection machines for thermoplastics. We recommend a melt temperature between 380°C and 400°C during the injection molding process. The mold temperature should be within a range of 160°C to 200°C, preferably 180°C. VESTAKEEP® 2000 CF30 is supplied as granules in 25 kg boxes with moisture-proof polyethylene liners. Inside the original and undamaged packaging, the product has a shelf life of at least 2 years when stored in dry rooms at temperatures not exceeding 30°C. Pigmention may effect values. For information about processing of VESTAKEEP® 2000 CF30, please follow the general recommendations in our brochure “VESTAKEEP® PEEK-Processing Guidelines“. The values presented are typical or average values, they do not constitute a specification.

Low- viscosity, unreinforced polyether ether ketone VESTAKEEP® 1000 G is a low-viscosity, unreinforced polyether ether ketone for injection molding. The semi-crystalline polymer features superior, thermal and chemical resistance. Parts made from VESTAKEEP® 1000 G are of low flammability. VESTAKEEP® 1000 G can be processed by common injection machines for thermoplastics. We recommend a melt temperature between 360°C and 380°C during the injection molding process. The mold temperature should be within a range of 160°C to 200°C, preferably 180°C. VESTAKEEP® 1000 G is supplied as granules in 25 kg boxes with moisture-proof polyethylene liners. Inside the original and undamaged packaging, the product has a shelf life of at least 2 years when stored in dry rooms at temperatures not exceeding 30°C. Pigmentation may affect values. For information about processing VESTAKEEP® 1000 G, please follow the general recommendations in our brochure “VESTAKEEP® PEEK Processing Guidelines“. The values presented are typical or average values, they do not constitute a specification.

Productprofil: PLEXIGLAS® 7N is an amorphous thermoplastic molding compound (PMMA). Typical properties of PLEXIGLAS® molding compounds are: good flow high mechanical strength, surface hardness and mar resistance high light transmission very good weather resistance free colorability due to crystal clarity. Special properties of PLEXIGLAS® 7N molding compound are: very good mechanical properties high heat deflection temperature very good flow / melt viscosity AMECA listing. Application: Used for injection molding optical and technical items. Example: optical waveguides, luminaire covers, automotive lighting, instrument cluster covers, optical lenses, displays, etc. Processing: PLEXIGLAS® 7N can be processed on injection molding machines with 3-zone general purpose screws for engineering thermoplastics. Physical Form / Packaging: PLEXIGLAS® molding compounds are supplied as pellets of uniform size, packaged in 25kg polyethylene bags or in 500kg boxes with PE lining; other packaging on request.